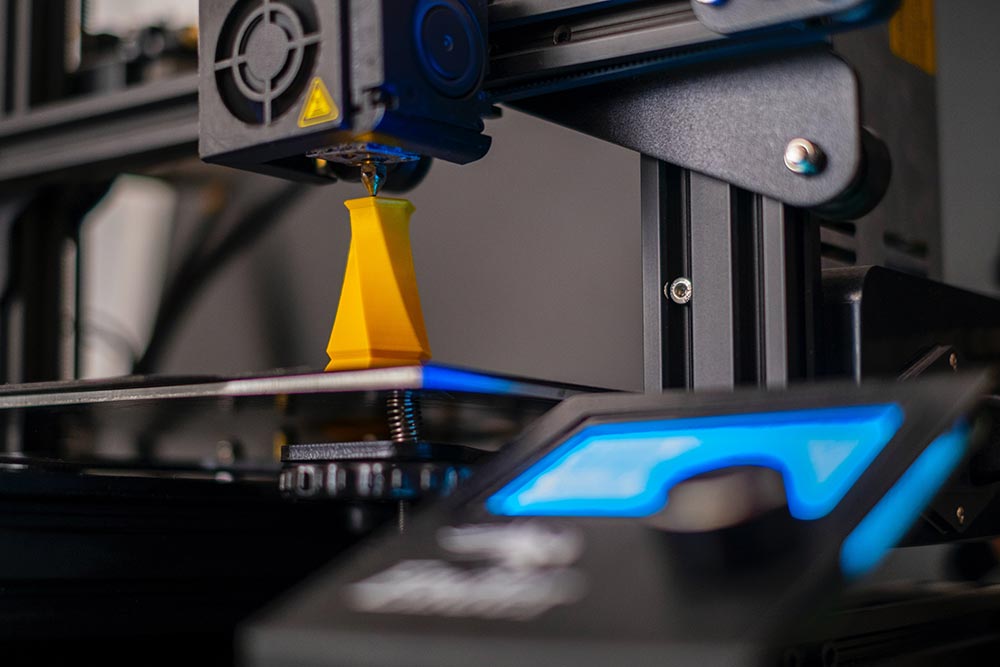

In recent years, 3D printing has become a powerful tool for innovation in various industries. From medicine to fashion, this technology can potentially change how we manufacture products and create solutions for complex problems. Let’s explore the basics, its applications, challenges, and potential future developments.

What is 3D Printing?

At its core, 3D printing is the process of creating three-dimensional objects from a digital model. The process is often referred to as additive manufacturing, as it entails layering materials on top of each other to form a three-dimensional object. This technique differs from conventional manufacturing methods like injection molding or CNC machining in that it permits more intricate designs and greater degrees of customization.

There are several types of 3D printers available, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each type uses different materials and techniques to create objects. Different techniques rely on distinct materials and processes to fabricate objects. For instance, FDM involves melting and extruding a filament made of thermoplastic material through a nozzle, building the object layer by layer. Conversely, SLA employs a liquid resin that solidifies when exposed to a UV laser to produce the desired shape.

The materials used depend on the printer type and the object’s intended use. Some common materials include plastics, metals, ceramics, and even biological materials like living cells. Using a variety of materials is one of the main advantages of this technology since it allows more flexibility in the design process.

Applications of 3D Printing

3D printing has a wide range of applications across various industries, including healthcare, engineering, architecture, and fashion. One of the most significant applications is in the medical field. Doctors and researchers use this technology to create customized medical implants, prosthetics, and even organs. For example, 3D printing has been used to create jawbone implants for patients with facial deformities and to create models of organs for surgical planning.

In the engineering industry, 3D printing is used to create complex parts and prototypes quickly and efficiently. Companies can use it to test different designs and iterate on them until they find the optimal solution. In the aerospace industry, it is used to create lightweight and durable parts for aircraft.

Architecture is another field that has been transformed by 3D printing. Architects can now create intricate models of buildings and structures using this technology, allowing them to visualize designs more tangibly. In the fashion industry, it is used to create unique and customized clothing and accessories.

Challenges and Limitations

One of the biggest challenges facing 3D printing is scalability. While it is great for prototyping and low-volume production, it can struggle to compete with traditional manufacturing methods when it comes to high-volume production. The speed and efficiency of 3D printing can be limiting factors when it comes to producing large quantities of parts or products.

Another challenge facing 3D printing is the quality of the printed objects. While it is wildly developed, it still struggles to match the precision and finish of traditional manufacturing techniques. The surface quality of printed objects may not be as smooth, and there may be visible layer lines.

Ethical considerations also come into play. One concern is the potential for copyright infringement. With 3D printing, anyone can create a replica of a copyrighted object, which can lead to intellectual property theft. Additionally, it has the potential to disrupt traditional manufacturing industries, which could have an impact on jobs and the economy.

Future of 3D Printing

Despite the challenges and limitations, 3D printing has the potential to revolutionize various industries in the coming years. One area of development is the use of new materials. Researchers are exploring the use of biomaterials, such as living cells, to create tissues and organs for transplantation. Another field of development is the use for construction. Companies are experimenting with large-scale 3D printing to create buildings and structures more efficiently.

Advanced printing techniques are also being developed, such as multi-material printing and hybrid printing. Multi-material printing allows for the use of multiple materials in a single print, which can create objects with more complex properties. Hybrid printing involves combining 3D printing with other manufacturing techniques, such as CNC machining, to create objects with more precise features.

Conclusion

3D printing has evolved incredibly since its inception and can change the way we manufacture products and solve problems in various industries. While there are challenges and limitations, advancements in technology and materials continue to push the boundaries of what is possible. As we look to the future, it will be exciting to observe how 3D printing will continue to evolve and impact our world.

Photo by Osman Talha Dikyar on Unsplash